Silicone mold casting is a widely used technique in the fields of industrial design and hardware product development services, serving as a versatile method for producing a range of products and prototypes. As aproduct design and development agency, we can appreciate the distinct set of pros and cons of this technology.

Pros:

- High Precision: Silicone molds can capture intricate details, making it suitable for replicating complex shapes and designs accurately.

- Versatility: Silicone molds can be used with a wide range of materials, including resins, concrete, wax, soap, and more. This versatility makes them suitable for various applications.

- Durability: Silicone molds are durable and can be reused many times without significant deterioration in quality, saving on material costs over time.

- Ease of Use: Creating silicone molds is relatively easy and doesn't require complex equipment. It can be done by hobbyists and professionals alike.

- Low Shrinkage: Silicone molds typically have minimal shrinkage, ensuring that the final castings closely match the original model.

- Temperature Resistance: Silicone molds can withstand a wide range of temperatures (200°C to 310°C), making them suitable for casting materials that require curing or setting at elevated temperatures.

- Flexible and Non-Stick: The flexibility of silicone molds allows for easy demolding of cast objects. They are also naturally non-stick, reducing the need for mold release agents.

- Cost-Effective: Silicone molds are often cost-effective, especially for small to medium-scale production runs, as they can produce multiple copies from a single mold.

Cons:

- Material Cost: High-quality silicone rubber can be expensive, which can affect the overall cost-effectiveness of the process, especially for large molds.

- Cure Time: Silicone rubber typically has a longer curing time compared to some other mold-making materials. This can slow down the production process.

- Air Bubbles: Trapped air bubbles can be an issue when pouring the casting material into the mold, leading to imperfections in the final product.

- Limited Material Compatibility: While silicone molds are compatible with many materials, they may not be suitable for all casting materials, especially those with aggressive chemical properties.

- Undercuts: Removing objects with complex undercuts from silicone molds can be challenging and may require multiple-part molds or additional demolding techniques.

- Tear and Wear: Over time, silicone molds can wear out or tear, especially if they are used frequently with abrasive materials.

- Size Limitations: Silicone molds are typically best suited for small to medium-sized objects. Creating large silicone molds can be challenging and may require more specialized techniques.

- Environmental Impact: The production and disposal of silicone molds can have environmental implications, particularly if the silicone used is not recyclable or biodegradable.

Application

Silicone mold casting is a versatile technique that finds applications in various industries and for a wide range of purposes. Some typical use cases for silicone mold casting include:

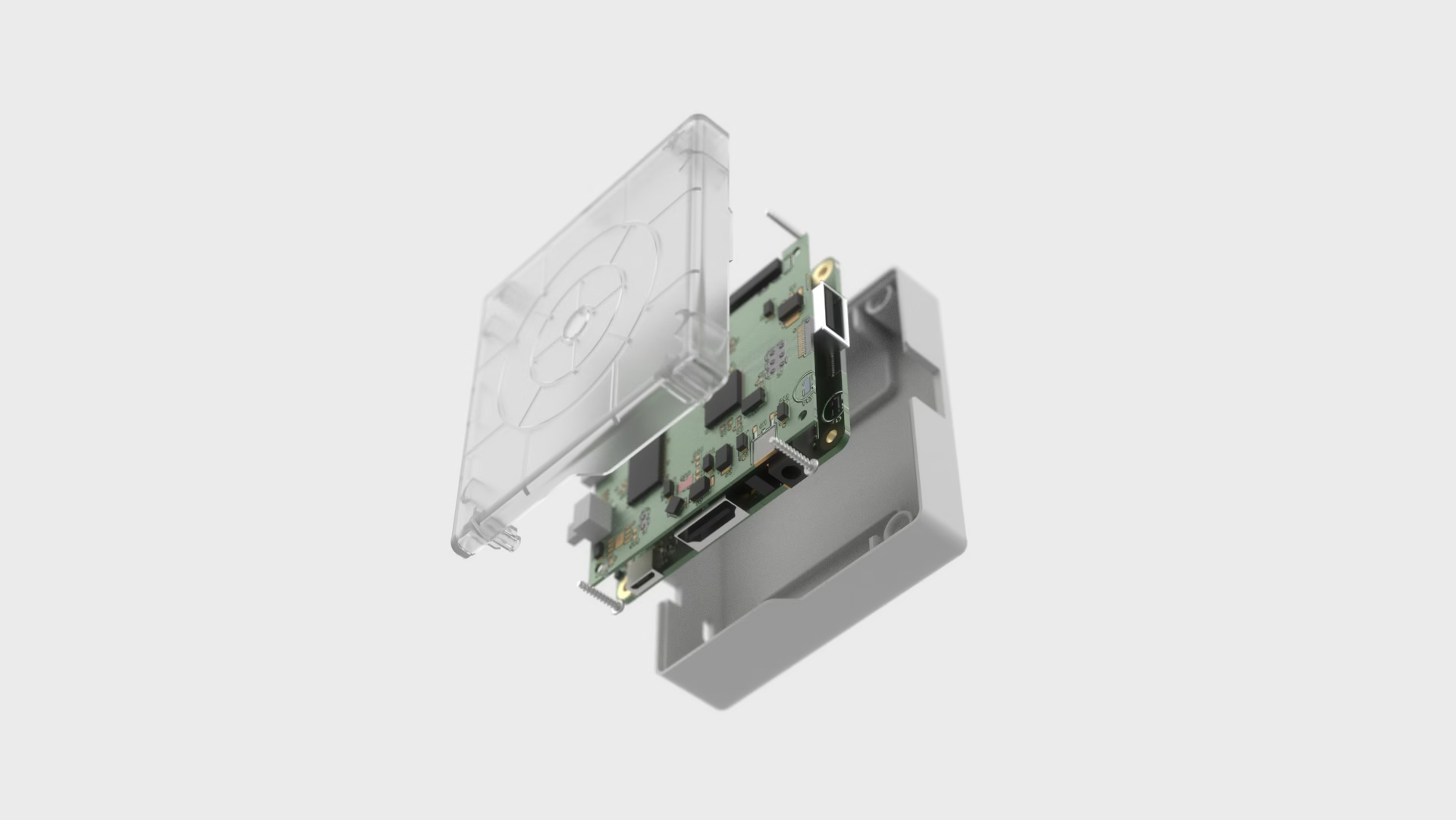

Prototyping of Plastic Goods: Silicone mold technology is frequently employed in the development of prototypes and scale models for consumer electronics, custom plastic enclosures, and smart devices in the realm of IoT. This enables designers to swiftly iterate and evaluate their concepts prior to full-scale manufacturing.

Automotive Parts and Repairs: Automotive enthusiasts and professionals use silicone molds to replicate and replace custom or hard-to-find parts, such as vintage car components.

Medical and Dental Prosthetics: Dentists and medical professionals use silicone molds to create custom prosthetic devices like dental crowns, hearing aids, and orthodontic appliances.

Aerospace and Engineering Prototyping: Engineers and aerospace professionals use silicone molds for creating prototypes of components, allowing for testing and validation before moving to production.

Materials and Tools Needed:

Original Part or Model: The object you want to replicate.

Silicone Mold Rubber: High-quality silicone rubber suitable for mold-making.

Release Agent: A substance to prevent the casting material from sticking to the mold.

Mixing Containers and Stirring Sticks: For preparing the silicone rubber and casting material.

Casting Material: The material you will use to create the parts (e.g., resin, concrete, wax).

Ventilation and Safety Gear: Adequate ventilation and safety equipment like gloves and eye protection if working with chemicals.

Steps to Make Silicone Mold:

- Prepare the Original Part:

- Make surfaces smooth if possible. Cover the part with primer and/or polish with sandpaper. It will make demolding much easier.

- Ensure that the original part or model is clean and free from dust or contaminants.

- If the original part has undercuts or complex shapes, consider how you will remove it from the mold later.

- Prepare the Work Area:

- Set up a clean and organized work area with good ventilation.

- Place the original part on a stable surface, preferably in a container or on a mold box to contain the silicone.

- Create a Mold Box (Optional):

- If needed, build a mold box around the original part to contain the silicone rubber. Use materials like cardboard, plastic, or wood.

- In case of two-part molds, use modeling clay to isolate regions of the part that shouldn’t be affected in casting of the first half.

- Apply a Release Agent:

- Coat the original part and the inside of the mold box (if used) with a suitable release agent to prevent the silicone from sticking.

- Mix Silicone Rubber:

- Follow the manufacturer's instructions to mix the silicone rubber. Typically, this involves combining a base and a catalyst in the specified ratios.

- Mix the silicone thoroughly to avoid inconsistencies.

- Always use two containers for mixing. There could be residues of unmixed components near the walls of the initial container.

- De-air Mixture:

- Put mixture in vacuum chamber.

- Use large containers. Liquid can expand up to five times due to extensive bubbling.

- Pour Silicone in Mold Box:

- Pour at the lowest point, allowing the silicone to flow around the master.

- Pour slowly to avoid bubbles.

- Do not pour directly over the master. This may cause a wave effect and potentially trap air.

- Allow Silicone to Cure:

- Let the silicone cure for the recommended time, typically several hours or overnight, depending on the type of silicone used.

- Cast Second part of the Mold (Optional):

- Remove part and mold from the mold box.

- Remove modeling clay.

- Repeat previous steps for the second part. In two-part molds, gates and vents are usually added to the second part.

- Demold the Silicone Mold:

- Carefully remove the silicone mold from the mold box (if used).

- Gently remove the original part from the cured silicone mold. If the original part has complex shapes or undercuts, consider cutting the mold into sections for easier removal.

Casting the Urethane Parts:

- Prepare the Casting Material:

- Mix the casting material following the manufacturer's instructions. This may involve adding pigments or other additives for desired properties.

- Pour the Casting Material:

- Pour the casting material into the silicone mold. Use a funnel or syringe for precision, especially for small molds.

- Allow Casting Material to Cure:

- Let the casting material cure or set according to its specifications. This can vary significantly depending on the material used.

- Demold the Finished Part:

- Once the casting material has fully cured, carefully remove the part from the silicone mold. Flex the mold to release the part gently.

- Trim and Finish the Part (if necessary):

- Trim any excess material or imperfections from the cast part.

- Finish the part as needed, such as sanding, painting, or assembling multiple parts together.

- Clean and Store the Mold:

- Clean the silicone mold and store it properly to prevent damage or contamination.

Repeat these steps as necessary to create additional parts from the same mold. Silicone molds are reusable and can produce multiple copies of the original part with consistent quality.

Conclusion

In conclusion, silicone mold casting stands as a fundamental and versatile technique in the realms of industrial design and hardware product development services. The process, which we have explored in detail in this article, offers a cost-effective and efficient means of producing a wide range of products and prototypes with precision and repeatability. While it has its distinct advantages, including the ability to reproduce intricate details and the potential for a low batch of production, it is essential to be mindful of its limitations, such as material selection and mold life.

As aproduct design agency, understanding the intricacies of silicone mold casting allows us to harness its potential and make informed decisions when selecting it as a manufacturing method for our projects. By combining our expertise with this versatile technology, we can continue to push the boundaries of innovation in the industrial design and hardware product development fields, ensuring that our clients receive the best solutions for their specific needs. With meticulous planning, attention to detail, and continuous improvement, we can leverage the strengths of silicone mold casting to turn ideas into tangible, high-quality products, fulfilling the needs and expectations of today's competitive markets.