The prototype is a tangible exemplar or embodiment, the prototype represents your conceptual product. Far from a culminating creation, it is merely a stepping stone. Utilized for various purposes such as market analysis, monetary appeal, or groundwork for manufacturing, a 3D virtual model occasionally suffices.

Primarily, the corporeal prototype facilitates an interaction with your conceived innovation. By examining its attributes and shortcomings, alterations to the design can be made, ensuring a functional end result.

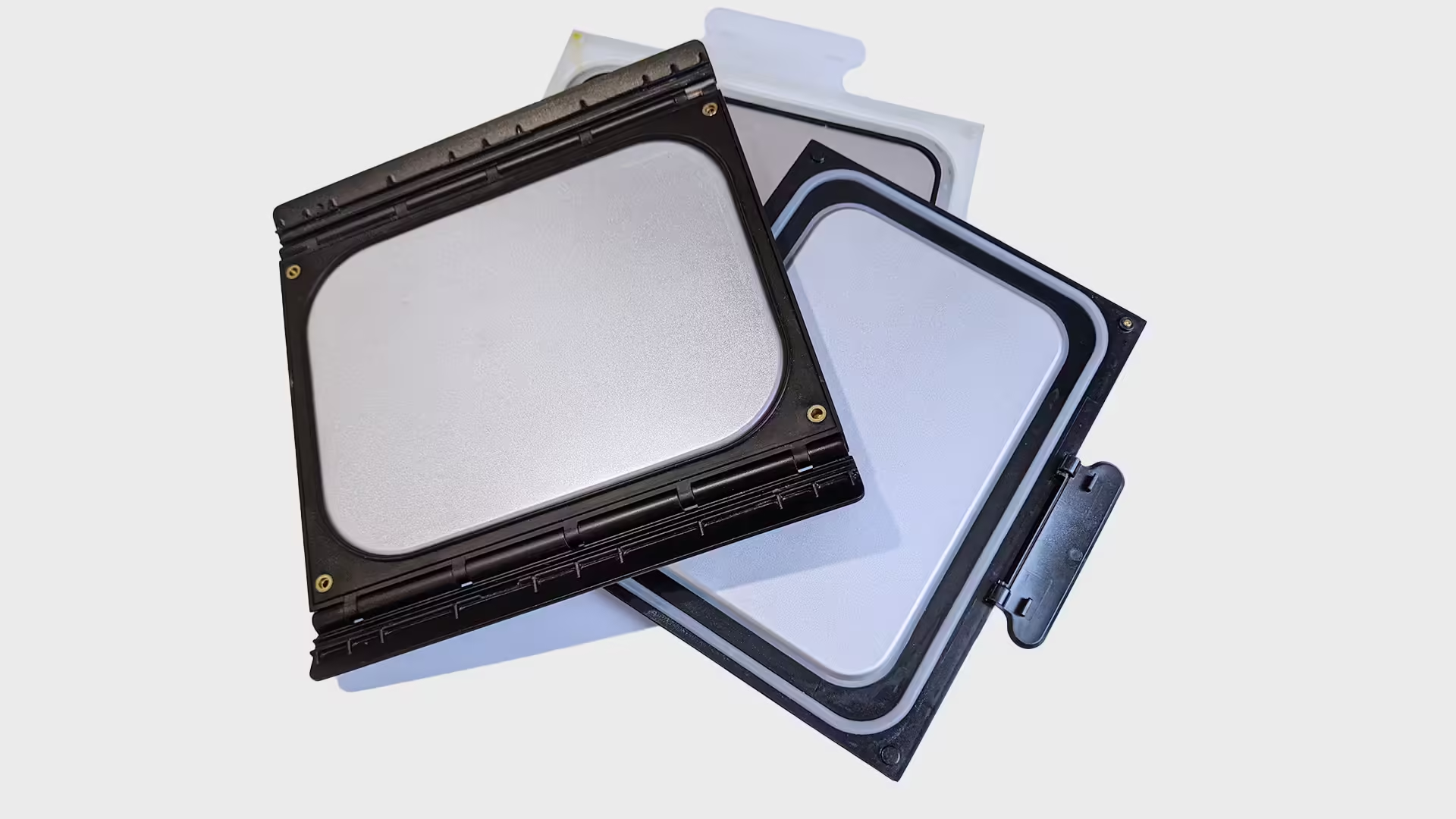

A A prototype turns your idea into reality, providing a tangible model to showcase materials, colors, and user experience. It allows for valuable insights and feedback from consumers, driving design refinements to enhance every aspect of your product.

The truth of the matter is that iterations prototypes are usually required to attain the ultimate harmony between functionality, performance, production costs, and visual aesthetics of said product. The more prototypes you have and the more time you invest in this iterative process, the higher the likelihood of achieving optimal outcomes, which will undoubtedly save you a pretty penny during manufacturing.

Avoiding the production of prototypes results in higher manufacturing expenses.

Product prototypes are essential for businesses across sectors and sizes. They enable thorough testing, refinement, and feedback integration, reducing risks and maximizing profitability. Prototypes serve as tangible evidence of feasibility and are powerful marketing tools to attract investors and generate customer interest. In today's competitive landscape, prototyping is a critical success factor, ensuring tested and proven ideas prevail.

An Minimum Viable Product (MVP) is a streamlined version of your product that highlights its core functionality, allowing you to gather crucial feedback from early adopters. Our skilled design and engineering team specializes in crafting interactive prototypes, enabling a seamless user experience during the initial stages of product development. By implementing an MVP, you can efficiently refine your product's features, saving time and development costs. This approach not only validates your idea's feasibility but also demonstrates its value to potential investors and partners. Harness the power of 3D printing and local manufacturing to create your MVP faster and more affordably than ever before.

The typical pathway for innovative creations to transform into lucrative products lies in advancing towards production and the subsequent sale of these products. Post the engineering phase, KDE stands ready to assist with the full process of prototyping and manufacturing your product. We offer an end-to-end service that takes you from the ideation stage to production and eventually to consumer sales. Our product portfolio is an equal mix of tangible inventions and electronics. Regardless, we take pride in being a comprehensive, in-house development company.

Certain creators merely aim to develop their invention to a level where they can subsequently certifications their concept to a pre-existing brand. Regardless of the chosen path, achieving a top-notch product design is an essential initial move. Remember, the more you advance your product, the greater the likelihood of obtaining certifications.

Fundraising is a common necessity in launching a hardware product. Primarily, before securing any funds, even from close associates or family members, it's critical to finalize at least the product design on your own. Moreover, the deeper you delve into the realms of engineering and particularly prototyping, the more appealing you become to potential investors. This not only enables you to attract more capital but also preserves more of your equity.

Prototypes are typically expensive, especially when compared to the cost of a finished product. Each prototype is a unique piece and requires a custom approach. Building 1 or 2 items of anything, in general, is pricey. But when we build prototypes, you also need to figure out how to do so. You're building something unique that didn't exist before, so there is no manual or instruction on how to do so. In addition to that, you will need a team of experienced professionals, expensive equipment, and materials. However, there are still ways how you can reduce the cost of your prototype. And now we are going to talk about seven of them.

Number one, only do what is required to achieve the goal of your prototype. If you only need a Ford for your testing, don't build a Mercedes.

Number two, do not start building another prototype until you've tested and evaluated your previous one and then incorporated the design modifications.

Number three, Collaborating to manage electrical and mechanical systems together is more cost-effective and efficient. Combining knowledge and skills from both fields makes changes easier and cheaper. This approach promotes smooth development and improves project effectiveness.

Number four, If your product is huge, start with a scaled-down prototype. It will cost significantly less, but will still provide useful data.

Number five, Use less expensive materials where possible, especially in the beginning. Let's say your product is designed to be metal. Try using plastic, if possible, to save costs on the materials and speed up the production process.

Number six, Use more automated equipment such as 3D printers, not only to cut the cost of the production process but also to save on the labor required to make your prototype.

Number seven, if at all possible, use off-the-shelf components as opposed to starting from the ground up and making your custom parts. See if you can find an existing product, disassemble it and use the parts from it. Use your ingenuity and good luck prototyping.

| Type of Prototype | Average Timeline |

|---|---|

| Custom PCB (Electronics) | 4-12 weeks |

| Looks-Like Prototype | 1-4 weeks |

| Works-Like Prototype | 2-4 weeks |

| Engineering Prototype | 4-12 weeks |

| Pre-Production Prototype | 4-12 weeks |

Inventors can benefit from partnering with prototype development companies that specialize in creating and refining product prototypes. Here are some things to consider when choosing a company:

Look for companies with experience in your industry or product category.

Conclusion: Prototyping is a crucial part of the product development process, as it allows for iterative design, testing, and refinement, ultimately leading to a better final product. By utilizing prototyping services, businesses can improve their product designs, reduce development costs, and increase their chances of success in the market.

To create a prototype, follow these general steps:

The cost of creating a prototype can vary greatly depending on factors such as complexity, materials, and the chosen prototyping technique. Simple prototypes can cost as little as a few hundred dollars, while more complex, high-fidelity prototypes can run into the thousands or tens of thousands of dollars. It's important to consider the goals and requirements of your specific project when determining the appropriate budget for your prototype.

Prototyping serves as a means to test and refine product designs before moving to full-scale production. It helps identify potential issues and allows for necessary adjustments to be made, ultimately leading to a better final product.

Prototyping benefits businesses by reducing development costs, improving product designs, and enabling faster time-to-market. It also allows businesses to test their product ideas with a minimum viable product, gather user feedback, and make data-driven decisions.

There are several types of prototypes, including proof-of-concept prototypes, functional prototypes, visual prototypes, and high-fidelity prototypes. Each type serves a different purpose and can be used at various stages of the product development process.

Businesses should consider using prototyping services during the product development process, particularly when creating a new product or making significant design changes to an existing product. Prototyping services can help identify potential design issues, reduce development costs, and improve overall product quality.

Submit an inquiry or get in touch with us through email or phone.

We will respond to you within 24 hours on business days.