Electronic product design and development is a complex, multi-faceted process that demands meticulous planning, execution, and collaboration. This comprehensive guide covers the essential steps to bring your innovative ideas to fruition, whether you're developing cutting-edge IoT devices, electronics products, or smart home solutions. With a step-by-step approach, we'll explore each stage of the development process, ensuring a thorough understanding of what it takes to create a successful electronic product.

Define target market and product requirements:

Begin by understanding your target market and establishing the product requirements. Research potential customers' needs, preferences, and challenges, and identify the key features and functionalities that set your product apart in the electronics product design space. Be sure to consider different user personas and use cases to ensure a well-rounded understanding of your target audience.

Conduct market research and competitive analysis:

Examine existing products, competitors, and market trends in electronic product development to pinpoint gaps and opportunities. This analysis will refine your product concept and offer valuable insights for data-driven decisions throughout the development process. Stay updated on emerging technologies and advancements in your industry to remain relevant and competitive.

Create a detailed product specification:

Develop a comprehensive product specification based on your research, outlining technical and functional requirements, target price point, and desired development timeline. This document serves as your team's blueprint throughout the electronic product design project, guiding the overall direction and ensuring a cohesive product vision.

Assemble a skilled team:

A well-rounded team is crucial for successful electronic product development. Consider various team structures, weighing their unique advantages and disadvantages, to determine the best approach for your project in the realm of electronics product design. Your team should include experts in hardware design, software development, mechanical engineering, and other specialized disciplines relevant to your product. More about how to assemble a team that best fits to your needs you can read in our post

Design the electronic circuit and select components:

With your team in place, design the electronic circuit by selecting appropriate components and creating a schematic. Balance performance, cost, and availability to achieve optimal results in electronic product design. Collaborate closely with your team to ensure a seamless integration of various subsystems, maximizing efficiency and reliability.

Develop a schematic and create a printed circuit board (PCB) layout:

Translate the schematic into a PCB layout, optimizing component placement and routing connections to enhance performance, reliability, and manufacturability in the electronic product development process. Utilize simulation tools and design-for-manufacturing (DFM) guidelines to identify and address potential issues before moving forward. More about create PCB layout

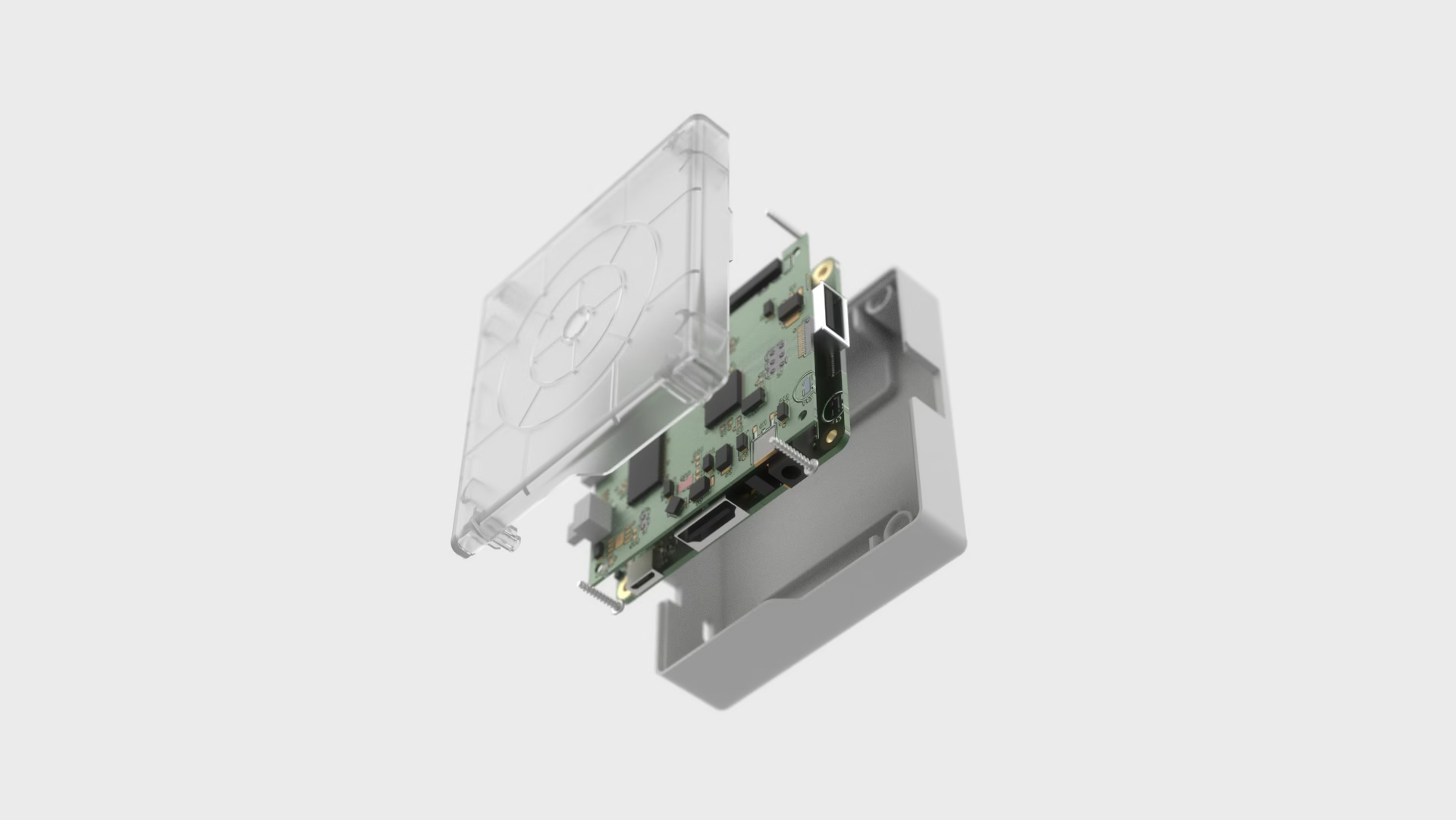

Design mechanical components and enclosures, and develop firmware:

Collaborate with mechanical engineers to design enclosures and other components, while firmware developers create software for seamless integration with the hardware in your electronics product design. Consider ergonomics, aesthetics, and durability to ensure a user-friendly and appealing product.More information about design process for hardware products in our article

Build and test prototypes:

Manufacture and assemble prototypes to assess performance, reliability, and usability, identifying issues that may necessitate design adjustments or component replacements in the electronic product development phase. Conduct rigorous testing, including environmental, stress, and lifecycle tests, to validate the product's reliability and durability under various conditions.More information about types of prototyping is in our article.

Iterate and refine the design:

Analyze testing results and gather user feedback to optimize performance and ensure the final product meets or exceeds customer expectations in electronics product design. This iterative process may involve multiple design revisions, ensuring a polished and well-engineered end product.

Prepare for manufacturing:

Source components and identify a reliable manufacturing partner, considering factors like production capacity, quality control, and logistics for your electronics product development. Develop a manufacturing plan, including process documentation, assembly instructions, and quality control measures, to streamline production and ensure consistent output.

Perform regulatory compliance and certification testing:

Ensure your electronic product complies with relevant industry regulations and standards before launching. This may involve testing for electromagnetic compatibility (EMC), safety, and environmental impact. Obtaining necessary certifications can help build credibility and trust with your customers while minimizing the risk of legal issues.

Launch the product and manage production, logistics, and support:

With your electronic product fully developed, tested, and certified, it's time to launch it into the market. Coordinate with your manufacturing partner to manage production, quality control, and inventory. Establish a robust logistics and distribution network to efficiently deliver your product to customers. Additionally, implement a customer support infrastructure to handle inquiries, warranty claims, and product updates.

Post-launch product management and continuous improvement:

Monitor your electronic product's performance in the market, gathering customer feedback and analyzing sales data to identify areas for improvement. Continuously refine and update your product to maintain relevance and success in the ever-evolving world of technology. Be prepared to adapt to shifting market trends, customer needs, and technological advancements to stay ahead of the competition.

The process of electronic product design and development is intricate and rewarding. By following these steps and assembling a talented team, you can transform your innovative ideas into successful products that delight customers and stand out in the competitive marketplace. Continuous improvement and adaptation are essential to maintain your product's relevance and success in the rapidly evolving technology landscape.

In the competitive world of electronic hardware product development, partnering with an experienced R&D team can provide significant advantages. Outsourcing your product development to a professional team like KDE ensures access to skilled engineers with expertise in customer electronics, IoT products, and smart home solutions. These experts have a deep understanding of the development process and can help you navigate complexities, optimize designs, and efficiently bring your product to market. The development time for an electronic hardware product can vary depending on the project's complexity, ranging from a few months to over a year. By working with an experienced team, you can reduce development time and minimize risks. The cost of outsourcing your product development to a team like KDE will depend on factors such as project scope, required resources, and timeline. With flexible billing rates and project arrangements, you can choose a pricing model that suits your budget and needs, ultimately creating a high-quality, market-ready product that stands out from the competition.